I. Regular inspections: ensure the running state of gears

1. Check the wear of gears

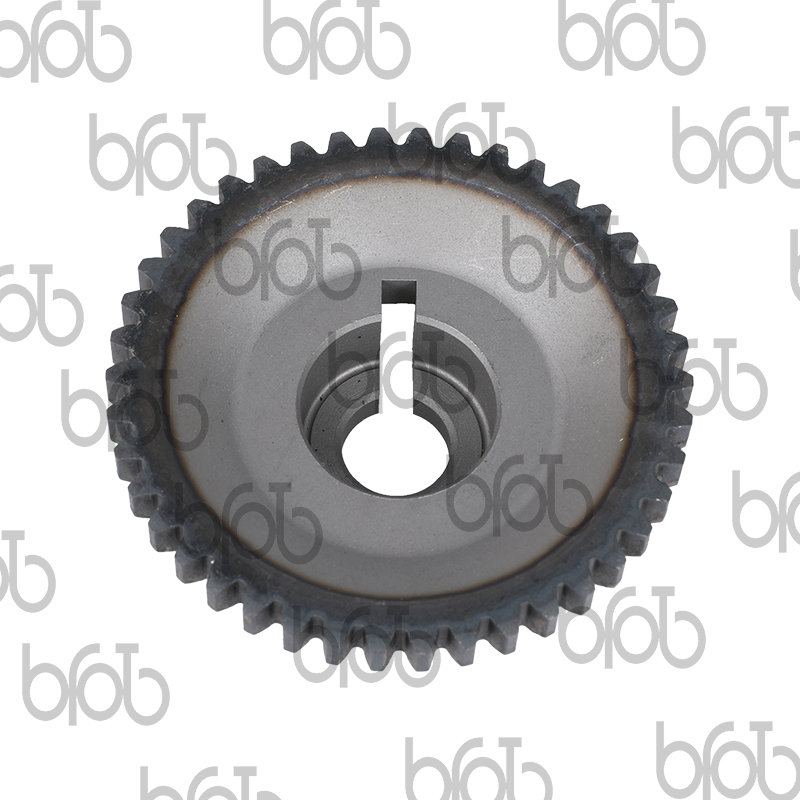

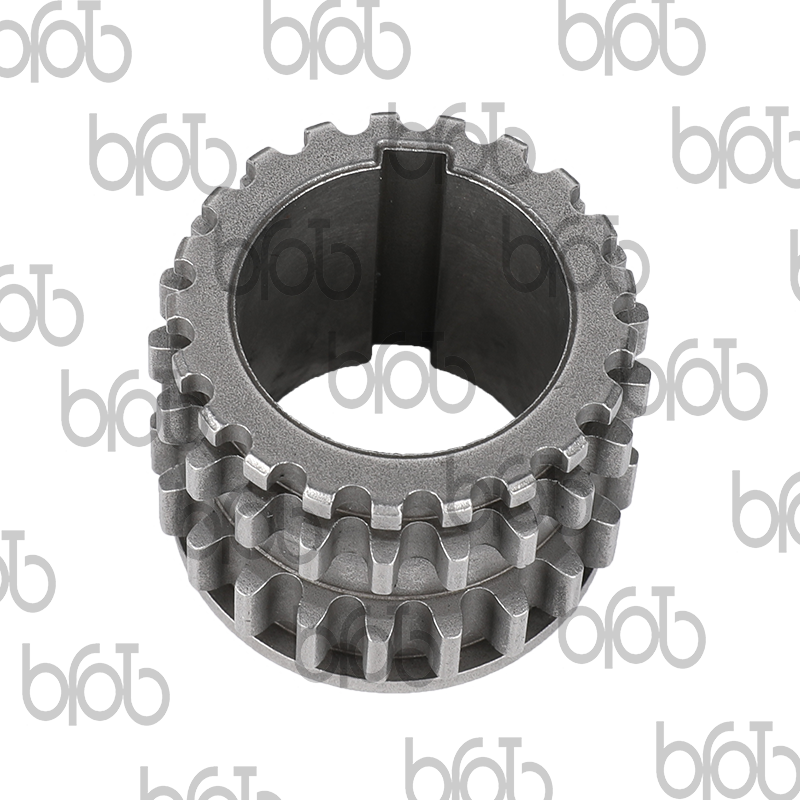

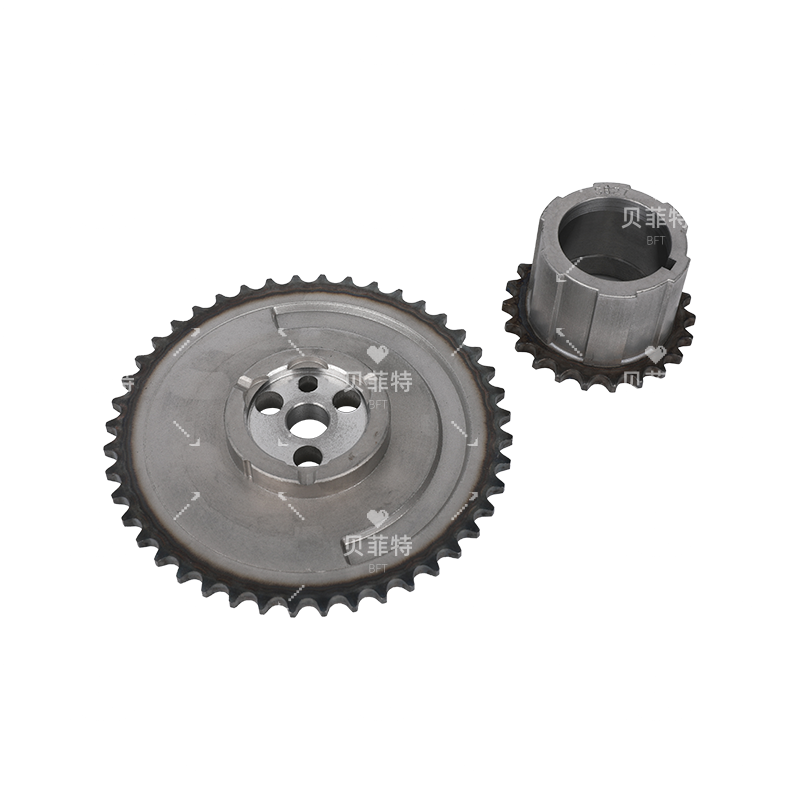

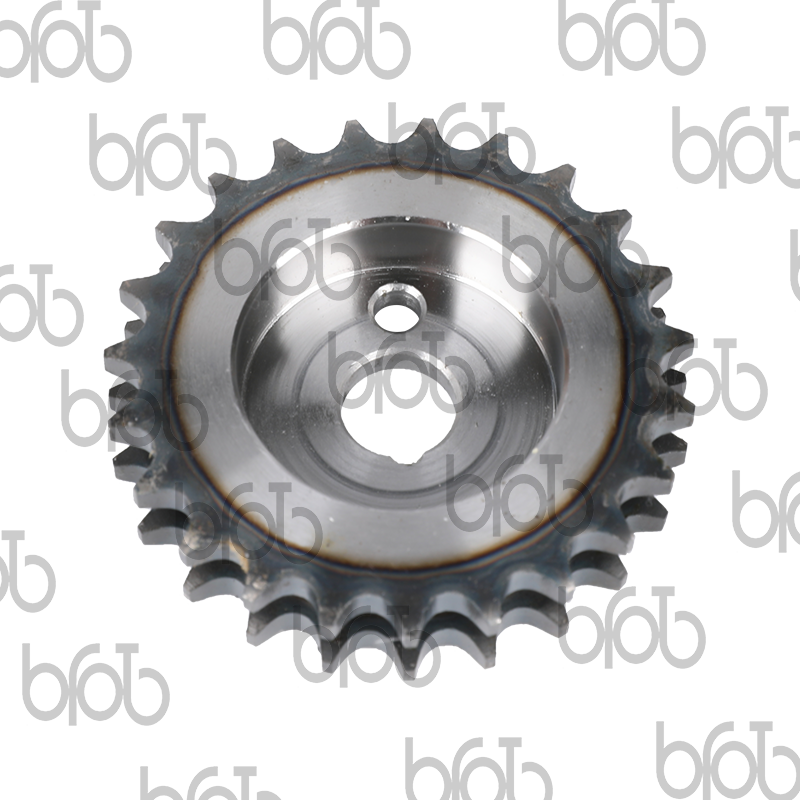

The camshaft gears work in a high-load, high-speed environment for a long time, and the surface of the gears will wear. Over time, wear will affect the gear tooth shape, precision and load-bearing capacity, which in turn affects the performance and working stability of the engine. It is very important to check the wear of the gears regularly.

When checking, first carefully observe whether there is obvious wear, cracks or gaps on the tooth surface of the gear. Minor wear can be alleviated by re-adjusting or adding lubricating oil, but if there is more serious wear or damage, the gear must be replaced in time. In addition, it is necessary to check the matching of the gear with other related parts (such as racks, valves, etc.) to ensure that they mesh properly.

2. Check the gear clearance

Gear clearance is essential for the normal operation of the camshaft gear. If the clearance is too large, it may cause poor gear meshing, noise, vibration, and even damage. When checking the gear clearance, a special clearance measuring tool can be used to measure the clearance between the gear and its meshing parts. If the clearance is too large, it is necessary to adjust or replace the relevant parts.

3. Check the positioning and fixing of the gears

The camshaft gears are usually connected to the engine through bearings or fixings to ensure that the gears are in the correct position and stable state. Check the fixing bolts and positioning pins of the gears regularly to ensure that they are not loose or damaged. If the bolts are found to be loose or the parts are abnormal, they should be reinforced or replaced in time to avoid abnormal wear or falling off of the gears due to improper position.

2. Lubrication and maintenance: ensure the smooth operation of the gears

The camshaft gears are inside the engine and work with other parts. Friction and temperature have a direct impact on their life. Lubrication is a key measure to prevent gear wear and overheating. Regular lubrication and maintenance can effectively extend the service life of the gears and improve engine performance.

1. Choose the right lubricant

Choosing the right lubricant is the basis for ensuring the good operation of the gears. The lubricant should not only have good viscosity characteristics, but also have anti-wear, anti-rust and anti-oxidation functions. According to the oil type and specifications recommended by the manufacturer, choose the right lubricant and ensure that the lubricant meets the working conditions of the engine.

2. Check and replace the lubricant regularly

As the use time increases, the lubricant will gradually lose its lubricating effect, become viscous or contaminated. Therefore, regular replacement of lubricating oil is a necessary step to keep the gears in good lubrication. When replacing, refer to the recommended oil replacement cycle according to the manual of the vehicle or machinery. When the oil quality is too poor or the contamination is serious, it should be replaced in advance.

3. Maintaining oil level and cleanliness

Maintaining the proper oil level is essential for the lubrication of the gears. Check the engine oil level regularly to ensure that it is within the normal range. When the oil level is too low or the oil is not clean, it will lead to insufficient lubrication, which will in turn increase the wear of the gears. It is important to avoid impurities (such as metal chips or dust) from entering the lubrication system, which will accelerate the damage of the gears. Therefore, it is also a necessary maintenance measure to clean the oil tank and filter regularly to avoid the accumulation of impurities.

3. Temperature management: avoid high temperature damage

The operating temperature of the camshaft gear has a profound impact on its life. Excessive temperature will not only make the lubricating oil lose its effect, but also cause deformation, increased wear and even fracture of the gear material. Therefore, the temperature management of the engine is very important.

1. Check the cooling system regularly

The cooling system of the engine is directly related to the operating temperature of the gears. Regularly check the coolant level, quality and whether there is leakage in the cooling system to ensure that the system can operate normally. At the same time, the working status of the radiator, fan and water pump should be checked to ensure that they will not cause the engine to overheat due to failure.

2. Avoid overload operation

Excessive speed or load will cause the engine temperature to be too high, resulting in damage to gears and other components. Therefore, it should be avoided to work under high load or high speed for a long time. Especially during the engine running-in period, it is necessary to follow the operating specifications recommended by the manufacturer, gradually increase the load, and avoid excessive use.

4. Regular replacement and adjustment

Over time, the camshaft gear may age or wear due to long-term use, affecting its performance. Therefore, regular replacement and adjustment of the gear is a necessary means to maintain its long-term normal operation.

1. Regular replacement of gears

Although high-quality custom camshaft gears have a long service life, it is a wear part after all, and long-term use will cause it to wear or damage. According to the frequency of use and working conditions, check the status of the gear regularly. If the gear is found to be obviously damaged or irreparably worn, it should be replaced in time. The replacement cycle of the gear is usually determined based on the manufacturer's recommendations or usage.

2. Adjust the gear meshing state

If the inspection finds that the gear meshing is poor, the gear clearance is too large or the meshing is not smooth, the corresponding adjustments should be made. The meshing of the camshaft gears, especially the gears related to the valve system, needs to be particularly precise. The slightest deviation may cause the valve timing to be wrong, thus affecting the operating efficiency and performance of the engine. The meshing accuracy can be restored by adjusting the gear position, adding shims or replacing related parts.

English

English Español

Español Deutsche

Deutsche